Every year, noise-induced hearing loss (NIHL) quietly steals hearing from millions of workers-often before they even notice it’s happening. Unlike a broken bone or a cut, NIHL doesn’t hurt. It doesn’t make you miss work right away. But once your inner ear hair cells are damaged by loud noise, they’re gone forever. No medicine, no surgery, no miracle cure can bring them back. And yet, this condition is 100% preventable. The problem isn’t that we don’t know how to stop it. The problem is that we keep ignoring the signs until it’s too late.

How Loud Is Too Loud?

You don’t need to be next to a jackhammer to risk hearing loss. The danger starts at 85 decibels (dBA)-the level of a lawnmower, a busy city street, or a power drill. The National Institute for Occupational Safety and Health (NIOSH) says that’s the threshold where damage begins. But here’s the twist: OSHA, the federal agency that sets workplace rules, still lets employers expose workers to up to 90 dBA for eight hours a day. That’s a 5-decibel gap between what’s legal and what’s safe. And that gap matters.

Sound doesn’t increase linearly. It grows exponentially. Every 3 dB increase doubles the energy hitting your ear. So if 85 dBA is the limit for 8 hours, then 88 dBA only lets you stay for 4 hours. At 91 dBA? Just 2 hours. At 94 dBA? Only 1 hour. And in many factories, mines, or construction sites, noise hits 100 dBA or more. That’s a chainsaw at three feet. At that level, your ears can take less than 15 minutes before damage starts.

NIOSH has been pushing for years to lower the limit to 85 dBA with a 3-dB exchange rate-the same math that makes sense in real life. But OSHA hasn’t changed its rules since 1983. That means millions of workers are being told they’re safe when they’re not. A 2024 study in Nature put it bluntly: "Occupational noise exposure limits do not prevent NIHL." The rules aren’t keeping people safe. They’re just allowing damage to happen slower.

Who’s at Risk?

It’s not just factory workers. The CDC tracks noise exposure across industries, and the numbers don’t lie:

- Construction: 22% of workers exposed to noise above 85 dBA

- Manufacturing: 19%

- Mining: 17%

- Agriculture: 15%

In construction, you’ve got jackhammers, saws, and pile drivers. In manufacturing, it’s presses, conveyors, and assembly lines running nonstop. Miners work with drills that scream at 110 dBA. Farmers deal with tractors, grain elevators, and combine harvesters. Even warehouse workers using forklifts or operating palletizers are at risk. And here’s the thing: most of these jobs don’t feel dangerous. There’s no smoke, no sparks, no visible injury. Just a constant roar that fades into the background.

But your ears don’t tune it out. They’re being worn down. The first sign? Trouble hearing high-pitched sounds-like birds chirping, doorbells, or women’s voices. You start asking people to repeat themselves. You turn the TV up. You avoid group lunches because it’s too hard to follow the conversation. That’s not aging. That’s noise damage. And it’s happening faster than most people realize.

What’s Being Done? (And Why It’s Not Enough)

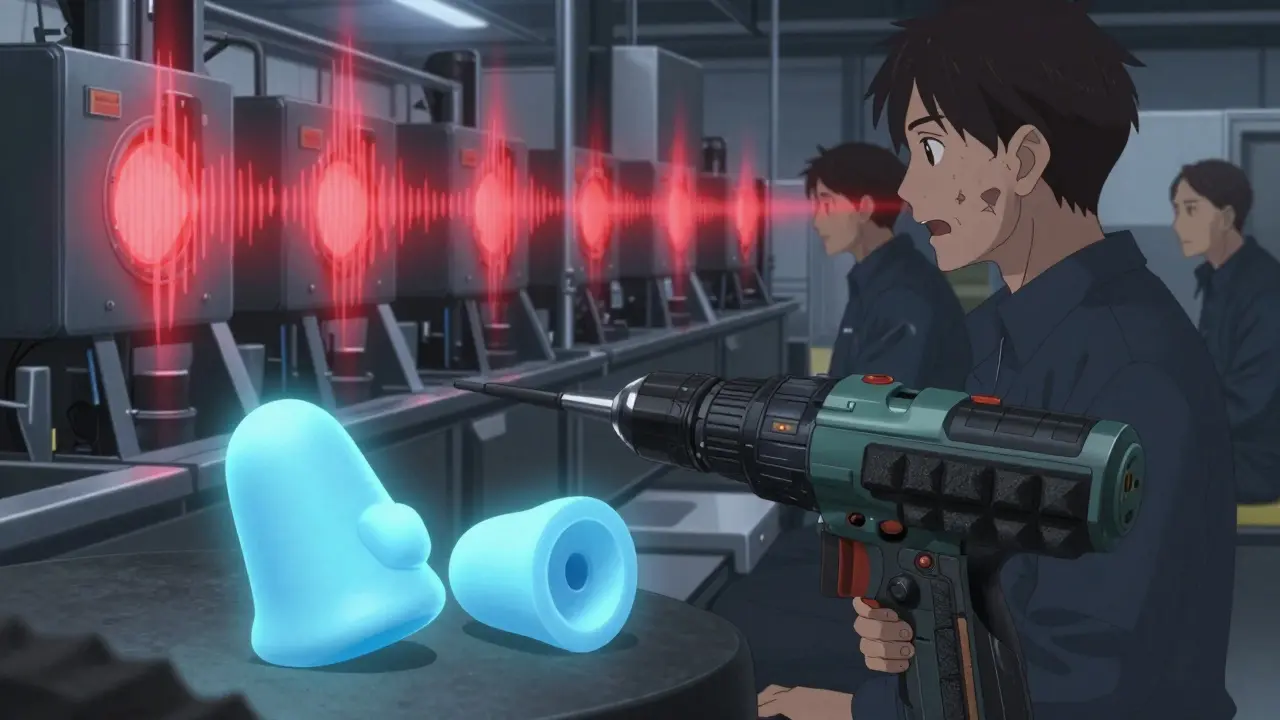

Most companies with noisy jobs have a "hearing conservation program." That usually means handing out foam earplugs and calling it a day. But here’s the problem: those cheap, disposable plugs? In real life, they only block 15 to 20 dB of noise-even though they’re labeled for 30 dB. Why? Because most people don’t insert them right. A 2017 Cochrane review found that 75% of workers put foam earplugs in incorrectly. They roll them too tightly, push them in too shallow, or forget to hold them until they expand. The result? Half the protection you paid for.

Custom-molded earplugs work better. They’re molded to your ear canal and give consistent 25-30 dB reduction. But they cost $50-$100 per pair. Most employers won’t pay for them. And even if they did, workers still take them out. Why? Because they can’t hear alarms, warnings, or coworkers. One Reddit user with 15 years on a construction site said: "Most guys take their earplugs out because they can’t hear equipment warnings or coworkers. Management provides cheap foam plugs that hurt after 2 hours." That’s not laziness. That’s a system that ignores human needs.

Engineering controls-things like sound barriers, quieter machinery, or enclosures-are far more effective. NIOSH studies show they can reduce noise by 10-30 dB. A mining operation in Wyoming dropped noise from 98 dBA to 82 dBA by installing acoustic enclosures around drills. Workers reported less fatigue, better concentration, and fewer headaches. But these upgrades cost money. And too many companies see them as optional.

OSHA requires hearing conservation programs only when noise hits 85 dBA. But enforcement is weak. In 2022, OSHA’s own data showed only 49% of manufacturing plants fully complied. Meanwhile, 30% of workers in those plants already had hearing loss. The system isn’t broken. It’s designed to let damage happen.

What Actually Works

The science is clear: the best way to prevent NIHL is to remove the noise at the source. That’s the first rule of the hierarchy of controls:

- Elimination - Don’t use noisy machines. Use quieter alternatives. NIOSH’s "Buy-Quiet" initiative, launched in 2023, lists over 1,200 low-noise tools and equipment. A drill that runs at 88 dBA instead of 102 dBA? That’s a 14 dB drop. That’s the difference between a 15-minute safe exposure and 2 hours.

- Substitution - Replace loud processes with quieter ones. Instead of hammering metal, use welding. Instead of pneumatic tools, use electric ones.

- Engineering Controls - Install sound-absorbing panels, enclose noisy equipment, or add vibration dampeners. In one factory, adding acoustic baffles cut noise by 18 dB. No worker had to wear a plug.

- Administrative Controls - Rotate workers so no one is exposed for more than 4 hours. Limit time in high-noise zones. But this is unreliable. A 2016 Cochrane review found effectiveness varied from 25% to 75% depending on how well it was managed.

- Hearing Protection - This is the last resort. It’s the only one that depends on perfect, consistent use. And as we’ve seen, that almost never happens.

Real success stories aren’t about handing out earplugs. They’re about changing the machines. In California, new rules passed in 2023 require employers to try engineering controls before relying on hearing protection. That’s the right order. It’s not about protecting workers from noise. It’s about removing the noise from their workplace.

The Hidden Cost

NIHL isn’t just a health issue. It’s an economic one. In 2022, the Bureau of Labor Statistics recorded 19,300 cases of hearing loss that forced workers to take time off. Each claim cost an average of $14,700. That’s $284 million in workers’ compensation payouts in one year. But that’s only the tip of the iceberg. Many workers don’t file claims. They just quit, switch jobs, or struggle silently.

And then there’s the human cost. People with hearing loss are more likely to feel isolated. They miss conversations. They lose confidence. Studies link untreated hearing loss to higher risks of depression and even dementia. It’s not just about not hearing a phone ring. It’s about not being able to hear your grandchild say "I love you."

But here’s the good news: every dollar spent on prevention returns $5.50 in savings, according to a NIOSH economic analysis. Better equipment, better training, better design-it all pays for itself. Fewer claims. Fewer lost days. Fewer workers quitting because they can’t hear anymore.

What Workers Can Do

You can’t control your employer’s budget. But you can protect yourself:

- Ask for better hearing protection. Demand custom-molded plugs if foam ones hurt or fall out.

- Learn how to insert earplugs right. YouTube has videos. Practice in front of a mirror. Hold the plug until it fully expands.

- Use noise-cancelling earmuffs over earplugs in extreme noise. Double protection works.

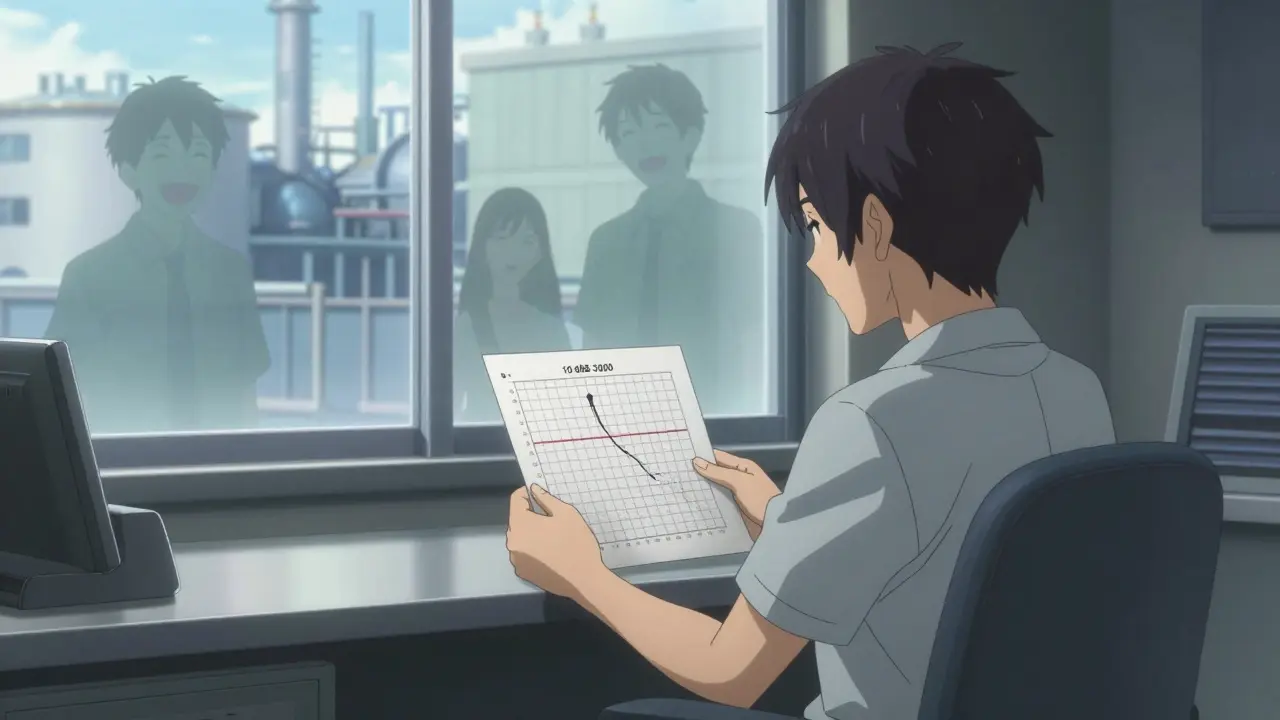

- Get your hearing tested every year. Baseline tests matter. If your hearing shifts 10 dB at 2000, 3000, or 4000 Hz, that’s a red flag.

- Speak up. If a machine is too loud, report it. Ask for quieter tools. Join safety committees.

Don’t wait until you can’t hear your alarm clock. Don’t wait until you’re asking people to repeat themselves three times. Hearing loss doesn’t come with a warning light. But it does come with a pattern: ringing in the ears after work, trouble understanding speech in crowds, needing the TV louder than before. Those aren’t normal. They’re early signs.

What Employers Must Do

If you run a business with noisy work:

- Measure your noise. Use a Type 2 sound level meter. NIOSH has a free app for iPhones that’s accurate to ±2 dB.

- Don’t rely on earplugs. Start with engineering fixes. Can you enclose the noise? Replace the machine? Install barriers?

- Train workers properly. Spend 10-15 minutes per person showing them how to insert earplugs. Validate with real-ear testing.

- Make hearing protection comfortable. Offer different types. Let workers choose.

- Track audiometric results. If you see a pattern of hearing loss, it’s not the workers-it’s the job.

- Get management involved. 92% of successful programs had leadership actively participating.

The best prevention isn’t a plug. It’s a quieter workplace.

Can noise-induced hearing loss be reversed?

No. Once the hair cells in your inner ear are damaged by loud noise, they don’t grow back. That’s why NIHL is permanent. You can manage it with hearing aids, but you can’t restore lost hearing. Prevention is the only cure.

What’s the difference between OSHA and NIOSH noise limits?

OSHA allows 90 dBA for 8 hours with a 5-dB exchange rate-meaning exposure time cuts in half every 5 dB increase. NIOSH recommends 85 dBA with a 3-dB exchange rate, which is far stricter. At 95 dBA, OSHA lets you work 4 hours. NIOSH says you should only be exposed for 30 minutes. The difference isn’t just policy-it’s the difference between safe and unsafe.

Are earplugs enough to protect hearing?

Not by themselves. Earplugs only work if they’re inserted correctly, worn all day, and fit well. In real-world use, most workers get only half the protection listed on the package. Engineering controls that reduce noise at the source are far more reliable. Hearing protection should be the last line of defense-not the first.

How do I know if my workplace is too loud?

If you have to shout to be heard by someone standing an arm’s length away, it’s too loud. If you hear ringing or buzzing after your shift, that’s a warning sign. Use a sound level meter app (like NIOSH’s) to check levels. Anything above 85 dBA for more than 8 hours requires action.

Do I need annual hearing tests if I wear earplugs?

Yes. Even if you wear protection, noise exposure can still add up over time. Annual audiograms track your hearing over the years. A shift of 10 dB or more at key frequencies (2000, 3000, 4000 Hz) means your hearing is changing-and something in your workplace needs to change too.

Tom Forwood

February 9, 2026 AT 23:32 PMI work in construction and this hits home. We get those cheap foam plugs that feel like they’re made of styrofoam and fall out after 20 minutes. I’ve had tinnitus for 5 years now. My boss says 'just deal with it' because 'everyone here has it'. We had a guy quit last month because he couldn’t hear his kid cry anymore. No one even blinked. It’s not about money-it’s about care.

John Sonnenberg

February 11, 2026 AT 01:25 AMThe system is designed to let damage happen. That’s not a metaphor. That’s the literal corporate playbook. OSHA hasn’t updated their noise rules since 1983. That’s the same year Tamagotchis were invented. We’re using 40-year-old safety standards to protect people from 2024-level noise. This isn’t negligence. It’s criminal.

Joshua Smith

February 12, 2026 AT 17:42 PMI appreciate how detailed this is. I’ve been wondering why my hearing tests keep showing a dip at 3000 Hz. I thought it was just aging. But now I realize I’ve been working next to a hydraulic press for 6 years. I never thought to question if the machine could be quieter. Maybe I should bring this up at our next safety meeting.

Jessica Klaar

February 13, 2026 AT 12:31 PMI work in a warehouse. The forklifts scream all day. I started using double protection-earplugs under earmuffs-and it changed my life. No more ringing after shift. No more headaches. But my manager said 'you’re overdoing it.' I showed him the NIOSH chart. He still didn’t get it. It’s frustrating when the people who should be helping you don’t even understand the science.

PAUL MCQUEEN

February 15, 2026 AT 10:49 AMI’ve seen this before. People always say 'it’s preventable' like that’s some kind of magic solution. But when you’re working 12-hour shifts and your union says 'we can’t afford better equipment,' what are you supposed to do? You can’t just wish noise away. The real issue is that we’ve turned workplace safety into a cost center, not a priority.

glenn mendoza

February 16, 2026 AT 05:19 AMIt is imperative to underscore that the scientific consensus is unequivocal: noise-induced hearing loss is irreversible and entirely preventable. Employers who neglect engineering controls are not merely failing to comply with ethical standards-they are perpetuating a systemic violation of human dignity. The economic argument alone, with a 5.5:1 return on investment, renders any counterargument untenable.

THANGAVEL PARASAKTHI

February 17, 2026 AT 16:09 PMI work in a textile factory in India. Noise is 95 dBA all day. We get no earplugs. No training. Just a sign that says 'wear protection.' We use rags to cover our ears. I’ve lost 30% of my hearing in 10 years. No one cares. Not even the government. This post is the first time I’ve seen someone outside my country even mention this. Thank you.

Chelsea Deflyss

February 18, 2026 AT 00:20 AMI work in HR. We have a guy who keeps complaining about noise. He’s 42. He’s got hearing loss. I told him maybe he’s just getting old. Turns out his coworkers have the same issue. We had to get a sound meter. It was 98 dBA near the stamping press. We fixed it. He cried. I didn’t know this was a thing. I’m sorry.

Scott Conner

February 18, 2026 AT 14:31 PMI tried the NIOSH app. My drill is 102 dBA. The manual says 90. I called the manufacturer. They said 'it’s within OSHA limits.' I asked if they’d use it in their own factory. They didn’t answer. This isn’t about safety. It’s about liability. They know. They just don’t care.

Alex Ogle

February 18, 2026 AT 23:06 PMI’ve been in mining for 22 years. The drills scream like a banshee. We used to get those foam plugs. Then we got custom ones. Then we got enclosures. The change? Night and day. I used to need a notepad to talk to my crew. Now I can hear them laugh. I used to get migraines every shift. Now I sleep through the night. The company didn’t do it because they were nice. They did it because workers started walking out. When you lose half your team because they can’t hear their own kids, you fix it. It’s not rocket science. It’s basic human decency.

Brandon Osborne

February 20, 2026 AT 12:54 PMYou people are pathetic. You want to spend $50K on sound barriers instead of just telling workers to wear their damn earplugs? You’re all just lazy. If you can’t handle a little noise, maybe you shouldn’t be in a factory. I’ve worked 30 years with no hearing loss. I wear one plug. That’s it. If you can’t handle it, go work in an office. This isn’t a cry for help. It’s a cry for accountability. Stop whining.