API Manufacturing: How Drugs Are Made and Why It Matters for Your Health

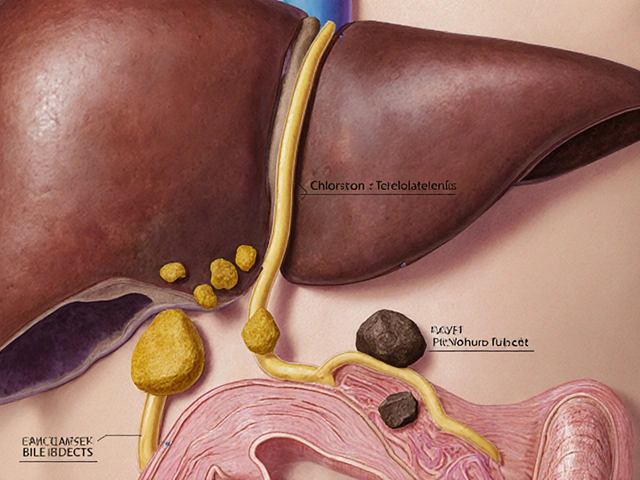

When you take a pill, the part that actually treats your condition is called the active pharmaceutical ingredient, the pure chemical compound responsible for the drug’s effect. Also known as API, it’s the reason your antibiotic kills bacteria, your blood pressure pill lowers pressure, or your painkiller stops the ache. But here’s the thing: API manufacturing isn’t just mixing powders in a lab. It’s a precise, regulated process that happens in specialized facilities around the world—and what happens there directly affects whether your medicine works, or puts you at risk.

Every generic version of a brand-name drug has to match the original in how fast and how much of the API gets into your bloodstream. That’s the FDA’s 80-125% bioequivalence rule. If the API isn’t made right—too impure, too unevenly mixed, or contaminated—it won’t absorb properly. That’s why generic drug absorption, how well the body takes in the active ingredient matters just as much as the name on the bottle. And when API quality slips, it doesn’t just mean a pill doesn’t work. It can lead to dangerous errors, like when look-alike, sound-alike drugs get mixed up because of poor labeling, or when steroid side effects turn deadly because the dose was off.

Behind every medication is a chain of people: chemists, quality control inspectors, and even whistleblowers who report safety violations. whistleblower protections, laws that shield workers who report unsafe manufacturing practices exist because mistakes in API production aren’t rare. A single batch error can ripple out to thousands of patients. That’s why pharmacies use two patient identifiers, barcode scanning, and strict labeling rules—to catch errors that started back at the manufacturing plant. Even something as simple as how you store your child’s antibiotic suspension ties back to how that API was stabilized during production.

API manufacturing isn’t glamorous. You won’t see it on TV. But if you take any medicine—even over-the-counter antihistamines or daily statins—it’s the reason you’re still breathing, moving, or sleeping. Poor API quality leads to drug shortages, treatment failures, and avoidable hospital visits. Good API manufacturing means your prednisone mood swings aren’t worse because of impurities, your nortriptyline doesn’t react badly with alcohol because of inconsistent dosing, and your COPD inhaler actually delivers the right amount of budesonide.

What you’ll find below isn’t just a list of articles. It’s a map of how API manufacturing connects to everything you care about: safety, cost, effectiveness, and your daily health. From how biosimilars are made to why your doctor recommends combination pills to cut your pill burden, every post here ties back to one truth: the quality of the active ingredient decides the quality of your care.

Causes of Generic Drug Shortages: Manufacturing and Supply Chain Vulnerabilities

Generic drug shortages are caused by manufacturing failures, reliance on foreign suppliers, low profit margins, and lack of backup systems. Millions of patients are affected every year-here’s why.